Facilities and Technology: Ensuring Superior Quality in Semiconductor Manufacturing

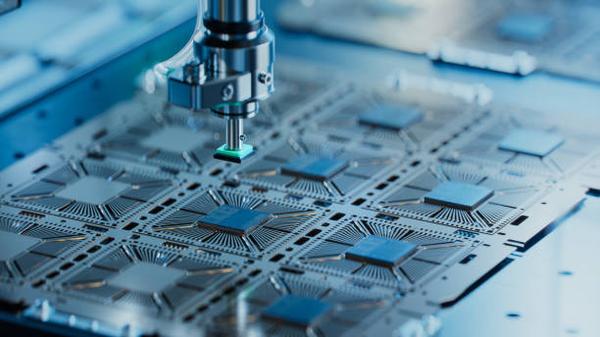

Semiconductor manufacturing is a complex and intricate process that requires state-of-the-art facilities and technology to ensure superior quality in the final product. The semiconductor industry plays a crucial role in powering various electronic devices, from smartphones to computers to medical equipment. As such, it is imperative for semiconductor manufacturers to invest in cutting-edge facilities and technologies to maintain their competitive edge in the market.

One of the key factors that contribute to superior quality in semiconductor manufacturing is the cleanliness of the facilities. Even tiny particles of dust or contaminants can negatively impact the performance and reliability of semiconductors. To prevent this, semiconductor manufacturers operate their facilities under strict cleanroom conditions. Cleanrooms are specially designed environments that minimize airborne particles through advanced filtration systems and controlled air flow. This ensures that the semiconductor manufacturing process is carried find out more in a pristine environment free from any impurities.

In addition to cleanroom facilities, semiconductor manufacturers also rely on advanced technology throughout the manufacturing process. One of the most critical technologies used in semiconductor manufacturing is photolithography. This process involves using light-sensitive materials and precise optical systems to transfer circuit patterns onto silicon wafers, which serve as the foundation for semiconductors. Photolithography requires highly sophisticated equipment such as steppers and scanners with extreme precision capabilities to achieve sub-micron resolution.

Another essential technology used in semiconductor manufacturing is chemical vapor deposition (CVD). CVD involves depositing thin films of materials onto silicon wafers through chemical reactions at high temperatures. This process allows for precise control over material properties such as thickness, composition, and uniformity, which are crucial for ensuring consistent quality across batches of semiconductors.

Furthermore, metrology tools play a vital role in maintaining quality control during semiconductor manufacturing. Metrology tools are used to measure various parameters such as film thickness, surface roughness, and critical dimensions with nanometer-level accuracy. By utilizing advanced metrology tools like scanning electron microscopes (SEMs) and atomic force microscopes (AFMs), semiconductor manufacturers can identify defects or deviations early on in the production process and take corrective actions promptly.

Overall, by investing in top-notch facilities and leveraging cutting-edge technologies throughout the manufacturing process, semiconductor manufacturers can ensure superior quality in their products. Cleanroom environments help prevent contamination issues while photolithography, CVD processes enable precise patterning and material deposition on silicon wafers. Metrology tools provide accurate measurements for quality control purposes.